Automation and software for Industry 4.0

State-of-the-art key technologies for complex tasks

GEFASOFT Automatisierung und Software GmbH develops, manufactures and sells automation systems for complex tasks in the manufacturing industry. The focus is on the global automotive, semiconductor and electronics industries as well as medical technology. Our core competencies include state-of-the-art automation technology, industrial image processing, laser systems and software development.

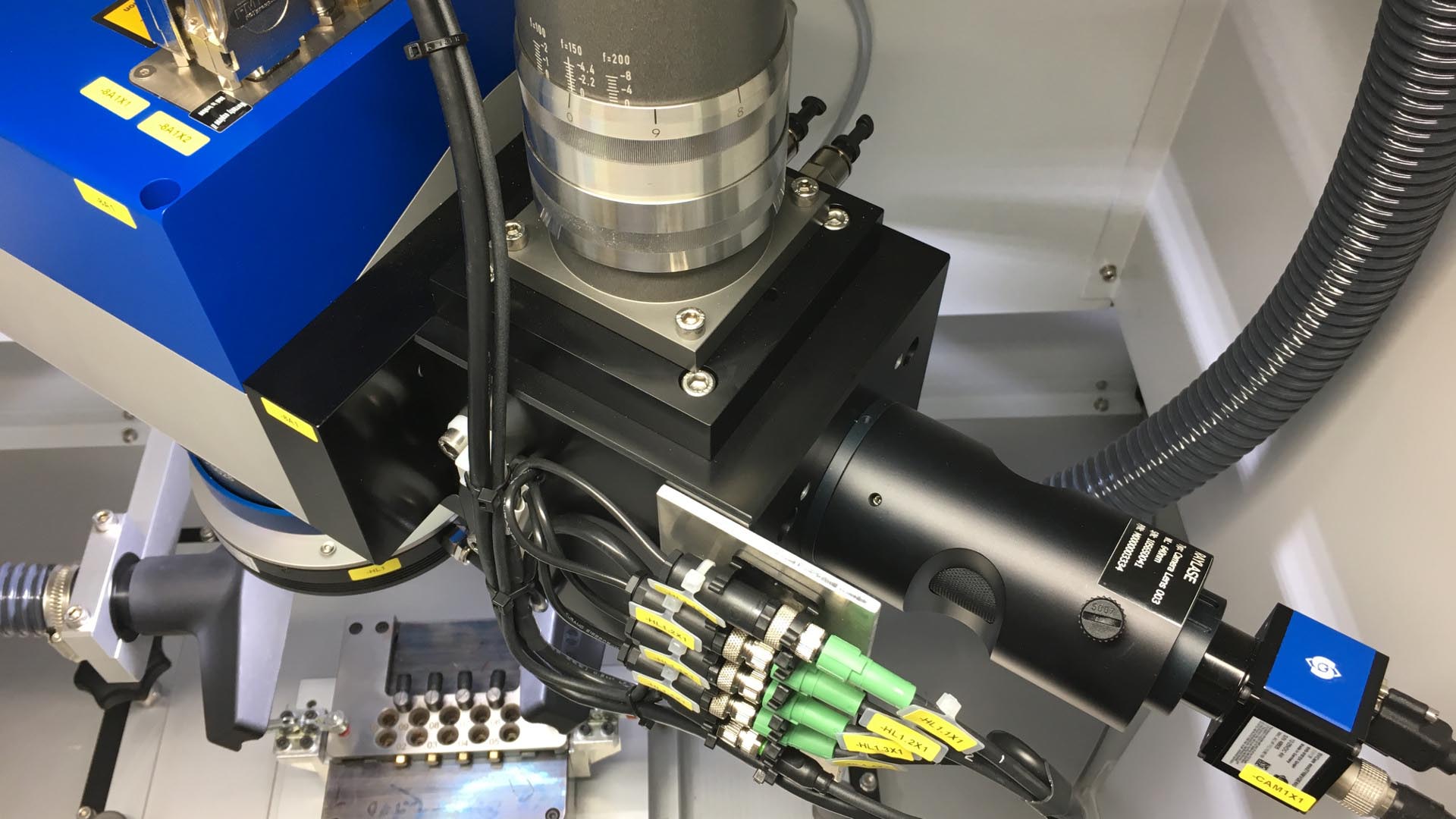

Laser systems and industrial image processing (vision) are among the key technologies in modern, industrial manufacturing. With the interactive functional integration of both technologies, effective and process-safe precision tools and networked production plants for Industry 4.0 are created.

WORKING AT GEFASOFT

Innovative capability and know-how lead determine our corporate success

The basis of our success is our employees. We are proud of our team of academics, engineers and qualified skilled workers. They represent more than 25 years of experience, curiosity and innovation.

GEFASOFT in Regensburg employs a wide range of talent: Engineers of all disciplines, mechatronics and precision mechanics, mathematicians and physicists, electricians and electronics technicians, industrial engineers and business economists. Teamwork and collegiality are lived values to solve the challenging customer tasks.

Automate better

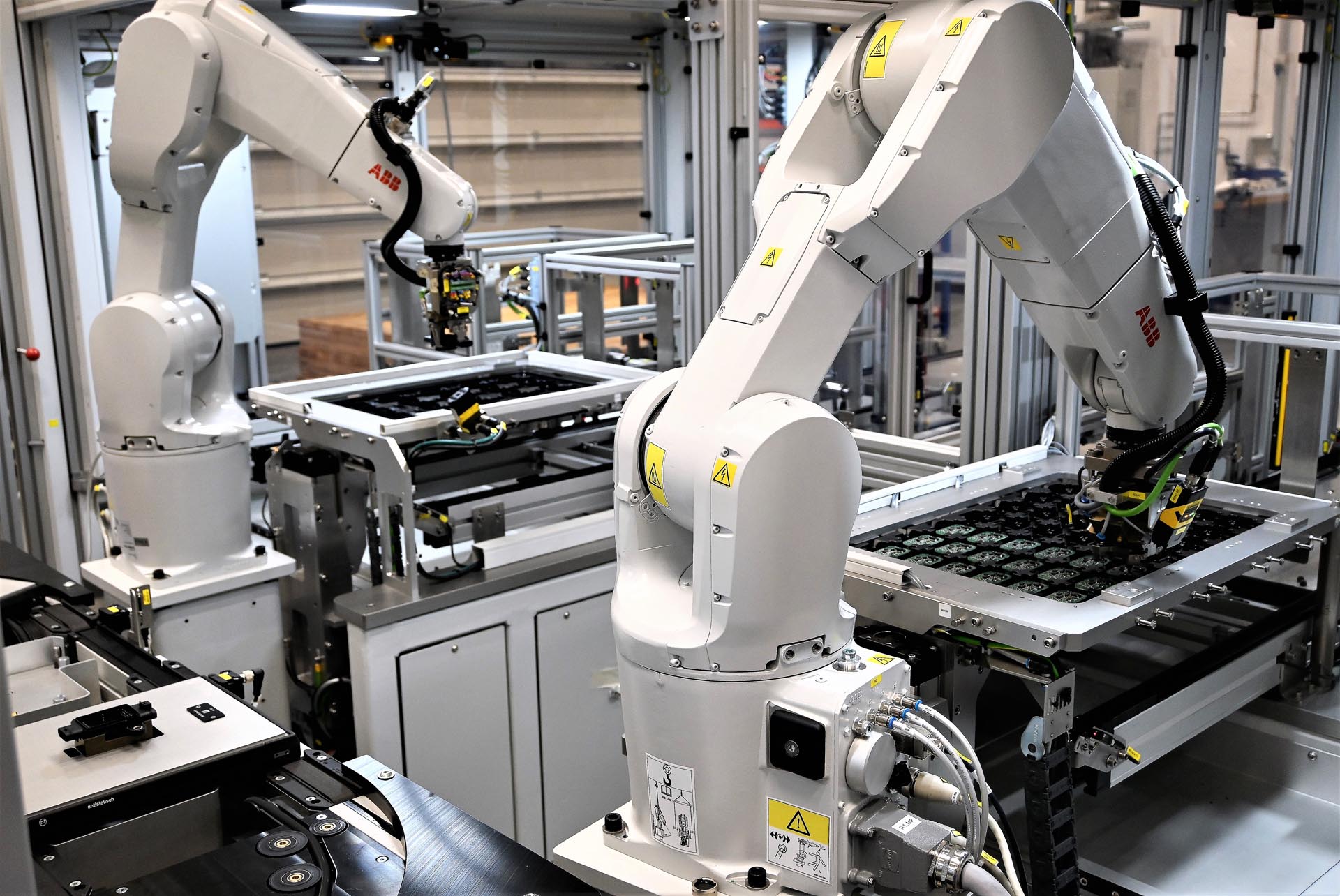

ln close consultation with the customer, we develop new processes and drive forward technical innovations. We enable the automated production of large quantities with the highest quality requirements.

Our Range of Services

Application-specific complete systems for laser material processing

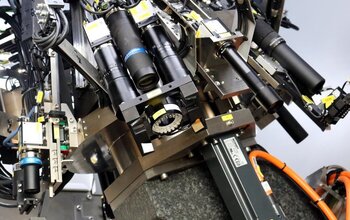

Customized solutions for automatic optical inspection and testing

![[Translate to Englisch:] Grafik Software Innovation](/fileadmin/user_upload/software_kachel.jpg)

High-level languages and PLC programming at the highest level

Flexible solutions for parts transport with robots

Development of complex automation systems with 3D CAD

Own parts production with axis and milling machines as well as lathe